Electronics manufacturing

Krüger & Gothe is specialized in producing complex electronic products in small, medium and large series. From order management to material supply

to complete production, including comprehensive testing, the company covers the needs of its customers. Many years of experience in all segments of activity form the basis for this.

ORDER MANAGEMENT

- Single orders

- Frame orders with Rolling Forecast

- Sample orders

- Urgent service

- Consignment stores

- Safety stocks

- Creation of order confirmations

- Central contact person for ordering issues

WORK PREPARATION

The work preparation of the Krüger & Gothe GmbH has technical and commercial alignment. The skilled engineerswith long-term experiencesare the central contact of the customers for all product-specific needs.

There will be Customer enquiries processed, Offers created and, when the contract is awarded, creates the conditions for proper production. The company's powerful ERP system plays an important role in this, because it is there that the Bills of materials, work plans and drawings deposited.

New manufacturing concepts and manufacturing technologies are also planned and designed in the work preparation phase and accompanied up to series production readiness and release. Afterwards the handover to production takes place. In extensive projects, e.g. Outsourcing of entire product packages or common Product developments is defined within the work preparation a comprehensive project management used to coordinate the various activities.

- Technical and commercial contact persons

- Customer quotation calculation

- preparation of tenders

- Qualification of new manufacturing technologies

- Project Management

- Creation of manufacturing concepts

- Creation of bills of material and routings

- Continuous production optimization

MATERIALS MANAGEMENT

A further central point of the Krüger & Gothe GmbH is, beside the production and various other functional areas, the material management. Due to the high Cost relevance and the high Market dynamicsToday, it is no longer sufficient to offer customers only a classic purchasing service. The Krüger & Gothe GmbH has recognized this and for many years now has been one of the most important unusually powerful

Materials Management built up.

The heart of materials management is the ERP systemwhich offers outstanding performance features to ensure that the large number of events and procedures can be processed promptly and securely. Also extensive Logistics concepts

like Consignment stores at suppliers to ensure availability.

The extensive material management is based on a global sourcing aligned. Thus the European and Asian Procurement market can always be used when the commercial, technological and quality framework conditions require it. Of course, only the Manufacturer used, which the Customer specifications fulfill.

The experienced Purchasing experts are also available to the customers in addition advisory to integrate the know-how of Krüger & Gothe GmbH into the Customer product development into the process.

- Single orders

- Frame orders with Rolling Forecast

- Sample orders

- Urgent services

- Electronic supplier connection

- Consignment stores

- Safety stocks

- Supplier evaluation, qualification & development

- Supplier Audits

- Material calculation for customer offers

- Identification of alternative manufacturers

- Last time by Management

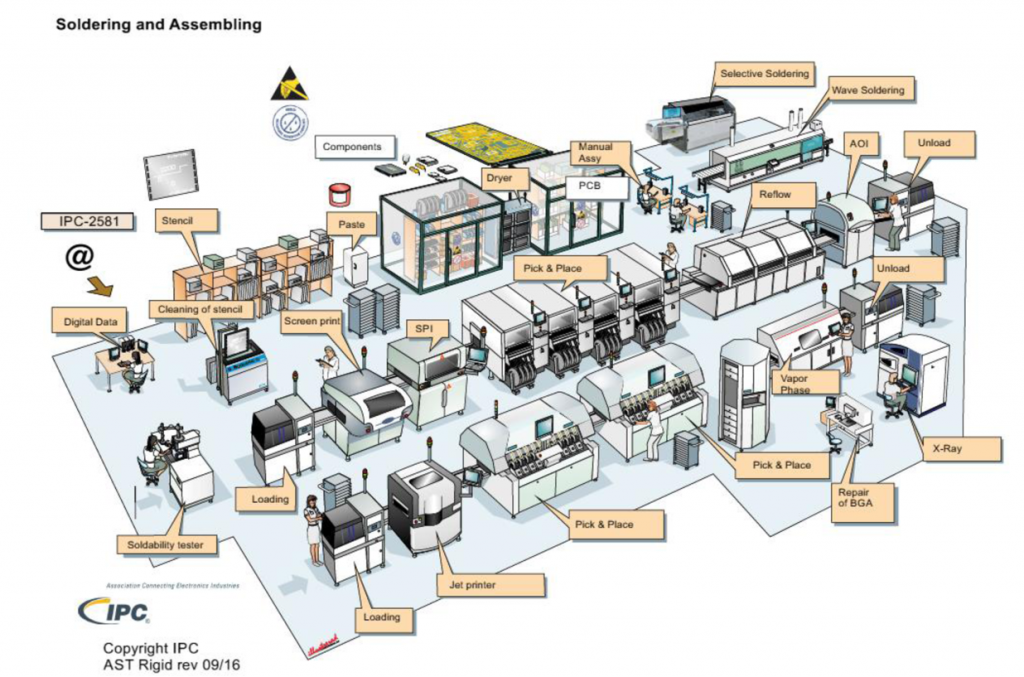

PRODUCTION

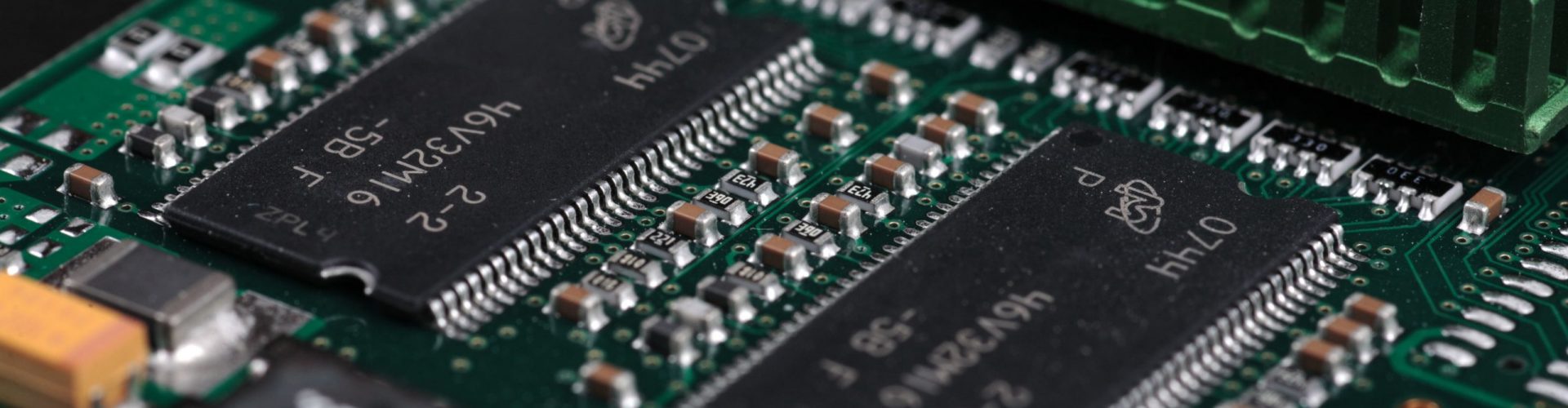

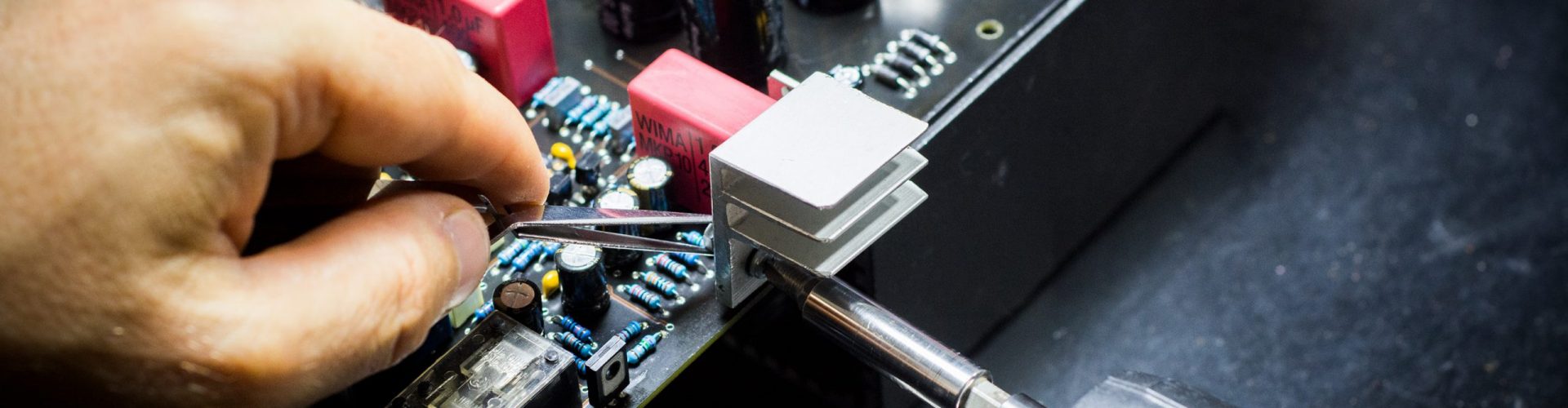

The Krüger & Gothe GmbH has a production, whose extent is unusual for a company of this size. Small quantities can be produced as well as medium and large quantities. We have an assembly capacity of 200,000 components per hour. In addition to this know-how in the SMD area, we have extensive machines and technologies available that entire breadth a modern electronics manufacturing can cover. For customers who require older technologies THT manual assembly stations at your disposal.

If necessary, the company is also able to customized production plants in order to produce on it in a cost-optimized way. This special performance feature and its solutions are already used today in complex products of Automotive industry to the mission.

In order to provide the customer faultless quality guarantee, the products are preferred electrical tests ...to the same... The test programs and concepts are usually, if not provided by the customers, in in-house design of the Krüger & Gothe GmbH.

- Six SMD lines of the latest generation

- One SMD line for samples and small series

- Various reflow and wave soldering systems - ROHS compliant overall processes

- Manual assembly

- Device installation

- Air conditioning and air conditioning systems

- Endurance Running Facilities

- Extensive test equipment (AOI systems, in-circuit test, insulation test, functional test, boundary-scan, final inspection equipment)

- Customized automatic production lines

- Casting and painting plants

- Rework stations for µBGA

- Assembly washing systems

- Laser marking cells

- Burn In